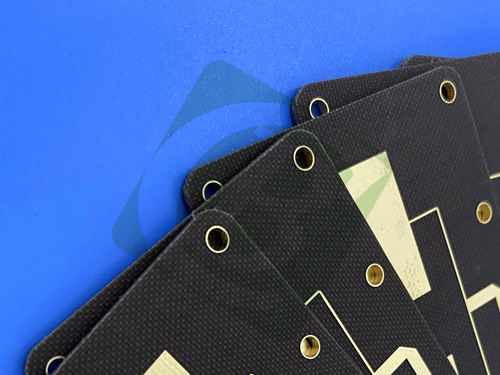

TLX-8 2-Layer 31mil ENIG PCB for Extreme Environment RF Applications

1.TLX-8 Introduction

TLX-8 is PTFE fiberglass laminates, a type of high volume antenna material which offers reliability in a wide range of RF applications. This material is versatile due to its wide range available thicknesses and copper cladding. It is suitable for low layer count microwave designs, offering mechanical reinforcement wherever a substrate experiences severe environments such as:

Resistance to creep for PWBs bolted to a housing that encounters high levels of vibration during space launch

High temperature exposure in engine modules

Radiation resistance in space (see NASA's website for low outgassing materials)

Resistance to extreme environments at sea for warship antennas

Resistance to a wide temperature range for altimeter substrates during flight

2.Benefits

Superior Signal Quality: Excellent PIM Values in PCBs (measured at lower than -160 dBc*)

Mechanical Reliability: Excellent Mechanical & Thermal Properties

Electrical Stability: Low and Stable Dk, Tightly Controlled DK, Low DF

Environmental Durability: Dimensionally Stable, Low Moisture Absorption

Safety Certification: UL 94 V0 Rating

Design Optimization: For Low Layer Count Microwave Designs

3.Main Properties

Electrical Properties

Dielectric Constant @ 10 GHz: 2.55 ±0.04 (IPC-650 2.5.5.3)

Dissipation Factor @ 10 GHz: 0.0018 (IPC-650 2.5.5.5.1)

Surface Resistivity Elevated Temp.: 6.605 × 10^8 Mohm

Surface Resistivity Humidity Cond.: 3.550 × 10^6 Mohm

Volume Resistivity Elevated Temp.: 1.110 × 10^10 Mohm/cm

Volume Resistivity Humidity Cond.: 1.046 × 10^10 Mohm/cm

Dimensional Stability

MD After Bake: 0.06 mm/M (IPC-650 2.4.39 Sec. 5.4)

CD After Bake: 0.08 mm/M (IPC-650 2.4.39 Sec. 5.4)

MD Thermal Stress: 0.09 mm/M (IPC-650 2.4.39 Sec. 5.5)

CD Thermal Stress: 0.10 mm/M (IPC-650 2.4.39 Sec. 5.5)

CTE (25-260°C)

X: 21 ppm/°C (IPC-650 2.4.41/ASTM D 3386)

Y: 23 ppm/°C (IPC-650 2.4.41/ASTM D 3386)

Z: 215 ppm/°C (IPC-650 2.4.41/ASTM D 3386)

Thermal Decomposition

2% Weight Loss: 535°C (IPC-650 2.4.24.6 TGA)

5% Weight Loss: 553°C (IPC-650 2.4.24.6 TGA)

Chemical/Physical Properties

Moisture Absorption: 0.02% (IPC-650 2.6.2.1)

Dielectric Breakdown: >45 Kv (IPC-650 2.5.6)

Flammability Rating: V-0 (UL-94)

4.PCB Construction Details

| Parameter | Specification |

|---|---|

| Base Material | TLX-8 |

| Layer Count | 2 layers |

| Board Dimensions | 25mm × 71mm = 1PC, ±0.15mm |

| Minimum Trace/Space | 4/6 mils |

| Minimum Hole Size | 0.3mm |

| Blind Vias | No |

| Finished Board Thickness | 0.8mm |

| Finished Cu Weight | 1oz (1.4 mils) outer layers |

| Via Plating Thickness | 20 μm |

| Surface Finish | Immersion Gold |

| Top Silkscreen | White |

| Bottom Silkscreen | No |

| Top Solder Mask | No |

| Bottom Solder Mask | No |

| Electrical Test | 100% tested prior to shipment |

5.PCB Stackup (12-Layer Rigid Structure)

Copper Layer 1 - 35 μm

Taconic TLX-8 Core - 0.787 mm (31mil)

Copper Layer 2 - 35 μm

6.PCB Statistics:

Components: 11

Total Pads: 34

Thru Hole Pads: 19

Top SMT Pads: 15

Bottom SMT Pads: 0

Vias: 27

Nets: 2

7.Typical Applications

Radar systems

Mobile communications

Microwave test equipment

Microwave transmission devices

Couplers, splitters, combiners, amplifiers, antennas

8.Quality Assurance

Artwork Format: Gerber RS-274-X

Quality Standard: IPC-Class-2

Availability: Worldwide